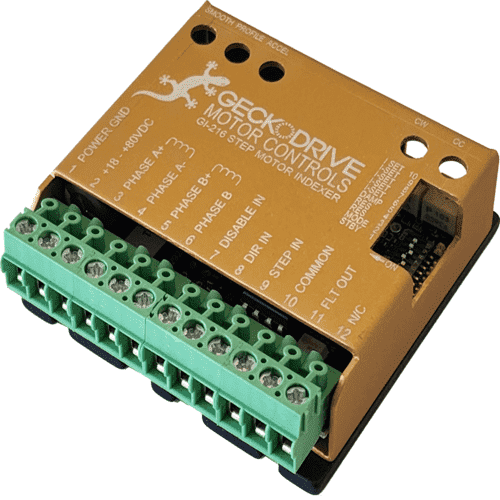

G216 INDEXING STEPPER CONTROLLER

Product Description

The all-new G216 Indexing Stepper Controller is the first in a new category of drives. The G216 can be sent a single pulse to start and stop motion at a user-settable speed using its onboard potentiometers, with three speed ranges to choose from. Maximum power ratings of 80VDC and 7A mean it will run even the largest stepper motors, and onboard protection circuitry prevents damage in the case of miswiring. Typical applications are indexing, automatic tool changers, conveyors, microscope stages, linear actuators, and any application the requires steady motion until commanded to stop. Limit switch inputs allow for easy wiring, and independent CW and CCW speeds with shared acceleration gives your application ultimate flexibility.

The G216 is a 7A, 80VDC step motor drive with an integrated voltage-controlled oscillator (VCO). It can be used as a step and direction input motor drive or as a dual input speed controller, with user adjustable CW and CCW speeds and acceleration profile. The operating mode and mode related functions are set via the 10-position slide switch on side of the drive. The G216 has 2 opto-isolated inputs for use in VCO mode or Step and Direction mode. The function of the input/outputs is also determined by the selected operating mode. The features of these operating modes are described below.

STEP MOTOR DRIVE FEATURES

The G216 can operate as a conventional STEP and DIRECTION input step motor drive.

MICROSTEPPING: The G216 has a 10 microstep native resolution; each full step angle of the motor is divided into 10 equally spaced microsteps so a 200 step per revolution motor has 2000 stopping locations per revolution.

STEP PULSE MULTIPLIER: The G216 synthesizes 10 microstep pulses for every full-step pulse and 5 microstep pulses for half-step pulse. The G216 acts like a full or half-step drive but motor has the smoothness of a 10-microstep drive.

SUB-MICROSTEPPING: For the 10 microstep resolution, each input step pulse is divided into 32 sub-microsteps resulting in a motor smoothness equal to a 320 microstep drive.

MORPHING: The G216 morphs from sine-cosine motor currents at low speeds to square-wave currents at high speeds. This technique extracts the maximum possible power from the motor at higher speeds. Morphing begins at 240RPM and ends at 360RPM.

MID-BAND RESONANCE COMPENSATION: The G216 uses active second-order damping to completely suppress a step motor’s tendency to resonate and stall at medium speeds (300RPM – 900RPM). This results in stable motor operation in this region.

LOW SPEED RESONANCE COMPENSATION: Low speed resonances are motor vibrations at speeds below 120 RPM caused by motor non-linearity. The PROFILE and ADJUST trimpots settings nulls these vibrations.

PROTECTION: The G216 is protected against motor to ground and motor to motor output short-circuits. It is also protected against reversed power supply polarity and power supply over-voltage. The internal fuse blows on polarity reversal and over-voltage.

AUTOMATIC STANDBY CURRENT: If enabled, the motor phase current is reduced to 70% of the set value and the G216 motor switching topology is changed to a low heating recirculating mode. This happens 1 second after the last step pulse is received.

VCO FEATURES

'ON THE FLY' MOTION CONTROL: Acceleration, velocity and destination can be changed even while the motor is in motion. The new values apply immediately.

CW and CCW LIMIT INPUTS: The G216 has an input for a limit switch on each end of travel. Once this switch is triggered the motor will decelerate to a stop and accelerate up to the opposite direction’s set speed.

Additional Details

Updating...

Updating...