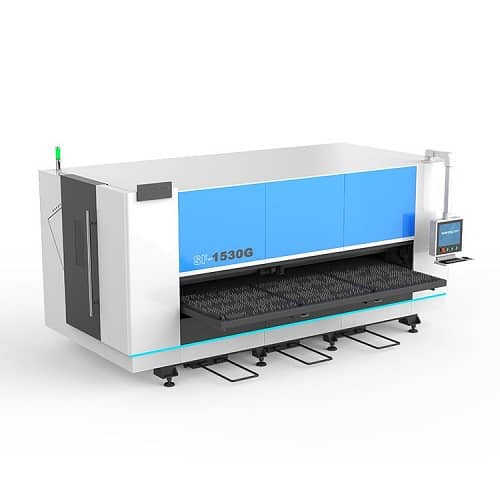

5′ X 10′ Fiber Laser Cutter for Metal Sheet with Single Table 1530G

Product Description

5' X 10' Fiber Laser Cutter for Metal Sheet with Single Table 1530G

847-984-0882 / automationtecinc@yahoo.com

- Power: 1,000 – 3,000 watts range (1kW-3kW)

- Working Area: 3000*1500mm or 118.11*59.06inches

- Numerical Control System: FSCUT2000

- Passed CE/FDA/ETL certifications

- 2 Year Warranty

- 24 / 7 / 365 Technical Support

Introduction

SF1530G is a single table fiber laser cutter machine for cutting metal sheet. The fiber laser power is 1kw/1.5kw/2kw/3kw. SF1530G has a small footprint (4890*2300mm/192.52*90.55inches) and low economic cost. The fully enclosed structure and the partitioned dust removal system help reduce environmental pollution. The pull-out platform is more convenient for loading and unloading materials. The metal sheet laser cutter passed CE/FDA /ETL certifications, which is in line with European and American standards.

Technical Parameters of SF1530G Fiber Laser Cutter For Metal sheet

| Model | 1530G |

| Working Area | 3000*1500mm or118.11*59.06inches |

| Laser Power | 1kw/1.5kw/2kw/3kw |

| Power Source | 380V,50Hz |

| X -axis Travel | 3000mm/118.11inches |

| Y -axis Travel | 1500mm/59.06inches |

| Z -axis Travel | 120mm/4.72inches |

| X/Y Axis positioning accuracy | ±0.05mm |

| X/Y Axis repeated positioning accuracy | ±0.02mm |

| Maximum Velocity of Movement | 80m/min or 3149.61inches/min |

| Maximum Acceleration | 0.8G |

Advantages of Fiber Laser Cutter

1.Fast Speed

The speed can reach 10m/min when cutting thin plates, and the speed of thin plate cutting is much faster than that of plasma cutting machines.

2.High Quality and Precision

- The cutting surface can be directly used for welding without grinding, the surface deformation is small, the roughness value is low, and the accuracy is high.

- Fiber laser cutting can accurately complete complex cutting with good edge quality.

- A precise laser beam can create components with precision tolerances in a fast, clean, and effective way without operator intervention.

3.Cost-Effective

- Maintenance costs are low, and cost-effective in cutting thin plates.

- Advanced software and narrow cuts allow the parts to be closely nested, thereby maximizing yield and reducing material waste.

Main Configuration of 1530G

1.Honeycomb Carbon Structural Steel Welding Bed

The bed is welded by high-quality steel plate and pipe. After welding, it undergoes stress relief annealing, secondary aging treatment, and precision machining on a large planomiller to ensure that the bed has sufficient structural stability, shock resistance and no deformation for long time.

2.Intelligent Spiral Surrounding Vacuum Dust Removal System

According to the current cutting position, this system automatically opens and closes the air outlet to perform partitioned air exhaust. At the same time, it cooperates with the bottom sealing structure design to achieve smokeless cutting.

3.Pull-out Platform

The worktable can pull out the bed 800mm, and at the same time it can use auxiliary equipment to load and unload materials.

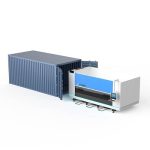

4.Packing

Save freight cost. Save installation time. Whole machine can fit into a 20-foot container.

What’s the Industry Application of 1530G Fiber Laser Cutter?

The SF1530G fiber laser cutting machine is specialized for sheet metal processing, machinery manufacturing, auto parts manufacturing, electrical manufacturing, elevator manufacturing, petroleum machinery, food machinery, decorative advertising, etc.

What does the SF1530G Affordable Fiber Laser Cutter cut?

Carbon Steel, Stainless Steel, Aluminum Alloy, Brass, Copper, Galvanized Sheet, Silicon Steel Sheet, Electrolytic Sheet, Titanium Alloy, Manganese Alloy, etc.

Cutting material and thickness in millimeters (mm)

| Material | 1kw | 1.5kw | 2kw | 3kw |

| Carbon steel(mm) | 0.4-12 | 0.4-16 | 0.4-18 | 0.4-20 |

| Stainless steel(mm) | 0.4-5 | 0.4-6 | 0.4-8 | 0.4-12 |

| Brass (mm) | 0.4-3 | 0.4-5 | 0.4-6 | 0.4-8 |

| Aluminum (mm) | 0.4-3 | 0.4-6 | 0.4-8 | 0.4-10 |

Cutting material and thickness in inches (inch)

| Material | 1kw | 1.5kw | 2kw | 3kw |

| Carbon steel(inch) | 0.015-0.472 | 0.015-0.629 | 0.015-0.708 | 0.015-0.787 |

| Stainless steel(inch) | 0.015-0.196 | 0.015-0.236 | 0.015-0.314 | 0.015-0.472 |

| Brass (inch) | 0.015-0.118 | 0.015-0.196 | 0.015-0.236 | 0.015-0.314 |

| Aluminum (inch) | 0.015-0.118 | 0.015-0.236 | 0.015-0.314 | 0.015-0.393 |

Cutting Samples

Five Star Fast Service System

1. High efficiency

- 24 hours a day (mainly for international), 7 days a week, 365 days a year at any time to receive repair calls;

- Within 10 minutes, technical engineers will consult, fix maintenance plan in one hour, and send engineers in one working day.

2. After-sale service

- The seller provides one time free installation and training in buyer’s factory. Seller pays for the airplane tickets and salary for engineers, buyer should provide accommodation and food to engineers.

- The seller will provide technical guide’s e-mail, telephone, WeChat, WhatsApp and so on.

- The seller should pay for the travel expense if local service needed within warranty time.

3. Warranty

- The warranty of laser source is 2 years.

- The warranty of the machine is 2 years (main spare parts), except for the consumable parts such as ceramic ring, focus lens, nozzle etc. Warranty counts from the date marked on the label of the laser source and machine.

- Except the damage artificially, seller is responsible for offering the fittings free of charge during the warranty period.

4. Worry-free

- Pre-sale service: theoretical + practical operation training, self-diagnosis training for common faults, guidance for quick repair of difficult faults, and warning of matters needing attention in use;

- Regular service: regular maintenance reminder, regular door-to-door service, regular promotional activities;

- Value-added services: equipment software and hardware upgrading services, financial leasing services, delayed warranty service.

5. Field Service

Our branches in United States, Germany, India, Pakistan, Serbia provide localized services and technical support for global customers.

Additional Details

Updating...

Updating...